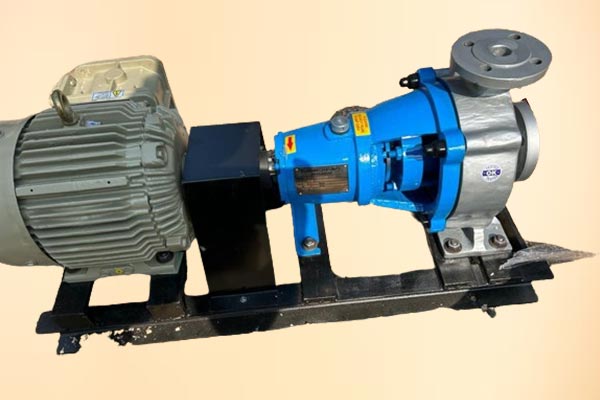

The chemical process pump FMCP is widely used for chemical, petrochemical industries, textile industries, organics industries, paper industries, oil refineries, pharmaceutical industries, cosmetic industries, solvent industries, food industries etc. to transfer and pumping the corrosive and non-corrosive liquid, organic liquid, food industries liquid, and oils, solvents and many more.

Design: The centrifugal pump FMCP is a horizontal end suction back-pull out pump accordance with DIN 24256 / ISO-2858. FMWP pump is design for high efficiency and trouble-free operation of pumping application. There is various 36 models available of FMWP pump for Lowest to high capacity & High-pressure range.

Shaft Seal Arrangement: Either a soft gland packing or a mechanical seal can be used. Stuffing box is design for gland packing and mechanical seal also. Stuffing box cooling can be provided for high temp liquid application.

Operating Range:

Max Flow – 400 m3/Hr.

Max Head: Up to 150 Meter

Max Pressure: Up to 16 Bar

Max. temperature: Up to 200 Deg. C.

Materials Of Construction:

Volute Casing – SS 316, SS 304, Cast Steel, WCB, And Other Alloys

Impeller – SS 316, SS 304, Cast Steel, WCB, And Other Alloys

Stuffing Box – SS 316, SS 304, Cast Steel, WCB, And Other Alloys

Shaft & SP Sleeve – SS 410, SS 316

Bearing Housing & Bearing Cover – Cast Iron

(MAPPING KEYWORD – CHEMICAL PROCESS PUMP, SOLVENT PUMP, ME PUMP,